Who needs lean manufacturing?

Have you ever gritted your teeth looking at graphs of steadily increasing production costs and a sales chart lags by a mile?

Then lean production is exactly what you need. Let’s Fix It! Let us overcome the Crisis in Manufacturing.

The Japanese have invented a new production model not from a good life too.

Did you know that in 1950, Toyota was making only 2,500 cars a year? Meanwhile, Ford was producing nearly 8,000 cars every day.

That time Japanese industry receives "special orders". In 1950, 96% of the total output was trucks for the American army. At that time, delivery time was more important than price, and manufacturer simply doubled the price for each car shipped.

Then the Americans left with their urgent orders. The old way of the company's survival was no longer suitable. Toyota had to ask itself the question:

What do our new customers want most?

It wasn’t "fast, on time." It was "good and inexpensive."

First, Toyota had to figure out what "good enough" means for a new client.

Top-manager of Toyota Taiichi Ono:

«Give the customer what he wants, how much he wants and when he wants».

Then they had to find a way to produce more with less waste, less time, and fewer resources.

Essence of new production management was identified.

THE BIG IDEA:

In order to improve efficiency, effectiveness, and profitability, focus relentlessly on eliminating all aspects of the manufacturing process that add no value from your customer’s perspective.

The core idea of Toyota production system is quite simple:

Relentlessly work on eliminating waste from the manufacturing process.

The Five Principles of Lean Production:

Focus on customer demand. What are they willing to pay for? Follow it. Align to it and adjust quickly.

Identify and define value.

Create a smooth pulling flow. Investigate your manufacturing process from upstream supply to downstream delivery. Does every operation really create customer value? Distinguish between activities that create value, are necessary waste, or are unnecessary waste.

Create a value stream map. As is – To be - Current status – Next most significant step.

Strive for excellence. Not fast, but steady.

Toyota introduced the Toyota Production System to its suppliers in 1965. Lean management in Japan goes beyond Toyota. This production system has pulled the Japanese out of the crisis.

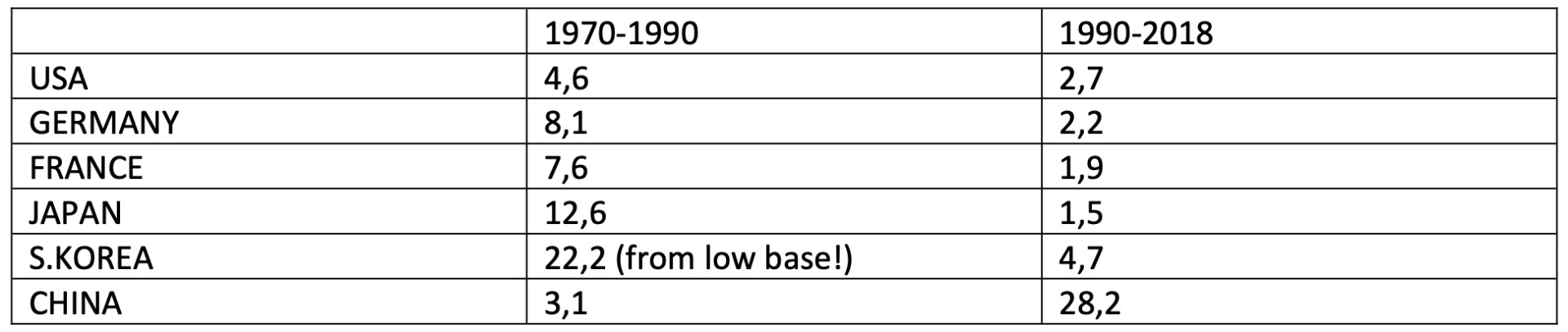

📈 GDP per capita nominal, USD

- and many have noticed this and adopted with a couple of decades lag. It was noticed because in the 1970s and 80s, many Western car companies faced a crisis: Japanese manufacturers offered high-quality cars at lower prices to their buyers. In the 1980s and 1990s, U.S. companies began embracing lean. They have realized that learning to improve processes usually pays off quickly.

Let's be honest.

Of course, you can disagree:

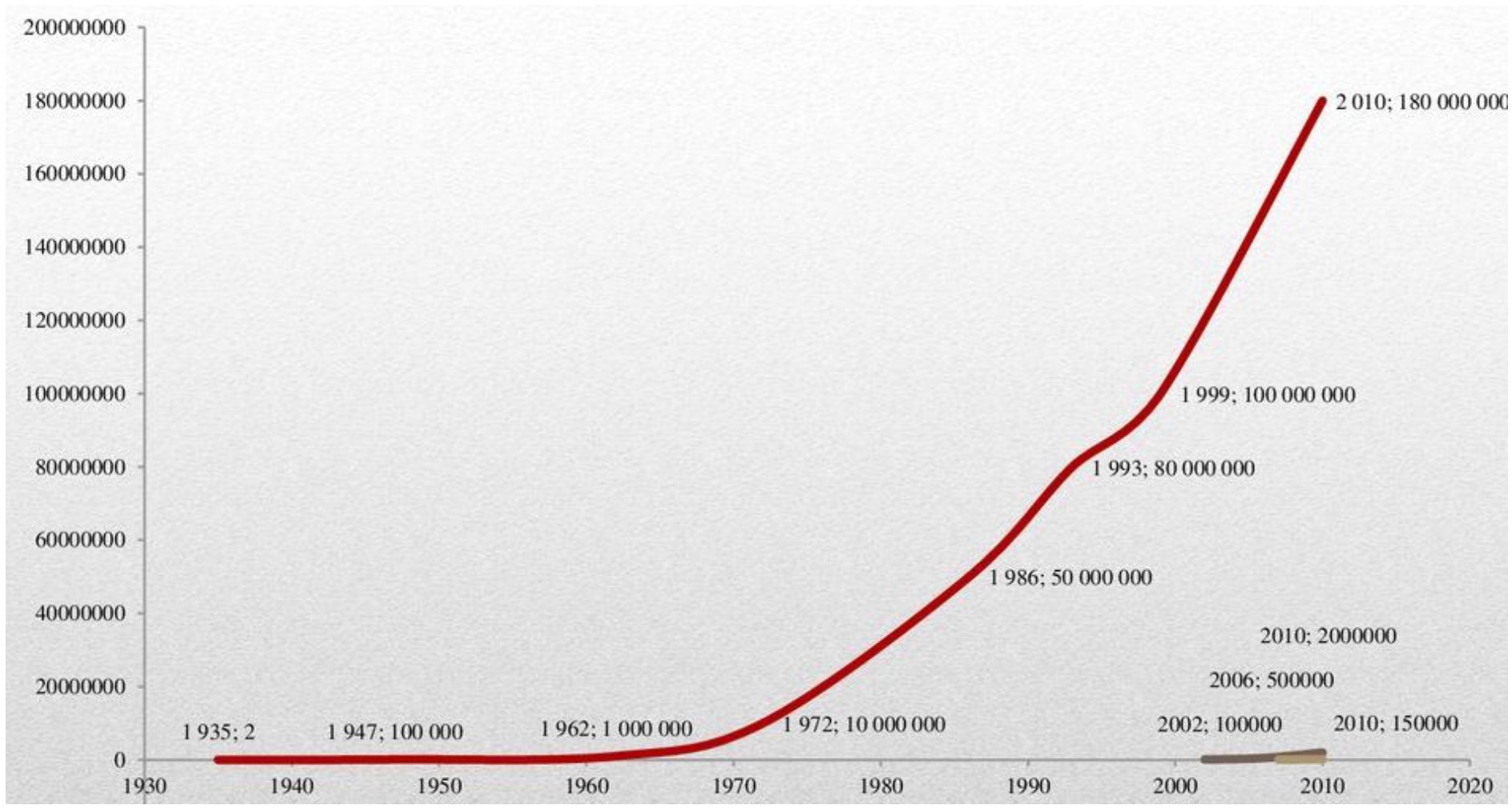

- Toyota quickly emerged from the crisis of the post-war years, not only thanks to the production management system invented by Taiichi Ono, but also due to other favorable factors outside the control of the company. It's true but no Japanese company has shown such rapid rise at the same time. The total volume of production of Toyota cars

- Over the past decades, Toyota has repeatedly failed both in terms of quality and in its place in global production. However, the most attentive researchers of Toyota's practices agree that these failures occurred precisely when, for various reasons, the company deviated from its principles of lean production. It was the analysis of these failures and a return to its fundamental principles that allowed Toyota to regain its leadership position so quickly.

SEVEN DEADLY WASTES (cornerstones):

Wastes can take many forms, but the underlying idea is to eliminate everything that does not add customer's value.

- Overproduction. Make the product no more than market demand.

- Waiting. Time when work-in-process is waiting for the next step in production.

- Unnecessary movement of people (movement that does not add value). Begin with 5S at least!

- Overprocessing. More processing than is needed to produce what the customer requires.

- Defects. This is often one of the more difficult wastes to detect and eliminate. But there are many effective instruments and procedures to avoid it. Ask Toyota!

- Overtransportation. Are you sure that your internal routes are optimal?

- Inventory. Distinguish between inventory that is necessary waste (buffering supply issues) and inventory that is unnecessary waste (internally generated). Incomplete production is a working capital cemetery.

An extremely important, but not represented within the Seven Deadly Wastes is unused human potential. To ignore it means to loose opportunities (e.g., lost motivation, creativity, ideas, lost employee contributions). The result is: responsibility for all lies squarely on the shoulders of management.

A few misconceptions about Lean Production

- Lean is often considered as a strategy for large corporations. But, in reality, Lean is not worse suited for smaller business: "It is easier to change the course of a boat than to move an iceberg."

- The majority of problems can be easily solved. How do you solve such a big chunk of problems at the bottom of the pyramid? This can be achieved by training and empowering all your people. When you allow the people who run the process to also do the improvements, they own the change and they support change and moving forward. "Motivation Gets You Started But Habit Keeps You Going."

- One day, you will reach the ideal state of your production settings. No, what was acceptable yesterday may be the focus for improvement today and tomorrow may need further work again. Continuous Improvement! The best is a contender for good.

- It is always possible to accurately calculate the economic effect of implementing a particular Lean tool. Sometimes you can. But having done one thing, you will immediately see that you can and should do the following. The synergy of successive changes will inevitably affect your business as a whole. The reduction in waste and defects will add additional money that can be invested in quality improvement, and the improved product quality will ensure higher profits overall. It's like an excellent perpetual motion machine, isn't it?